|

By Lois Kerr

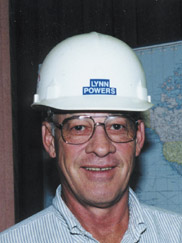

The production department, the largest division at the Sidney Holly Sugar plant during campaign, has the responsibility of extracting the sugar from the beets, which involves removing impurities and crystallizing the remaining juice into sugar. Production duties begin as soon as beets, unloaded from the trucks, hit the wet hopper. Production continues through the slice, the diffusion process, the purification and carbonation procedures, and the evaporation of the juice to produce crystals. Production continues until the white sugar has passed across the production scales on its way to storage in the silos. It takes approximately 18 hours for a beet entering the wet hopper to end up as white sugar on its way to the silos for storage. Lynn Powers, production manager at Sidney's Holly Sugar, supervises the nearly 200 employees that operate the factory production equipment. This year, employees sliced an average of 6,100 tons of beets per day in their efforts to process the sugar. "We set a new daily slice record this year by slicing an average of 6,100 tons per day," Powers says. The majority of the production process has become computerized. "This is the first year we've been rid of the old control panel," Powers remarks. "We now rely on computers and monitors." He adds, "We still have areas in the factory that are not totally computerized, but even in those areas we now have a better grasp of what's going on." Prior to computers, production crews relied on charts, graphs and pneumonic air controls. Crews did more manual labor, and relied more heavily on instinct and experience. "Computers just make a more consistent product," Powers explains. Every year, the factory runs slightly differently than the previous year, based on the quality of the beets. The real key to factory production is purity, and purity dictates the way the factory operates. In the field, growers concern themselves with sugar content and yield. In the factory, production crews concern themselves with the amount of impurities in the beets. Impurities include such things as excessive nitrogen, sodium and potassium. A higher quality beet slows the slice, as the factory works to extract every bit of available sugar. However, sugar is easier to extract from a high quality beet, and the factory uses less lime in the process, and equipment runs better. A low quality beet speeds up the slice, as there isn't as much sugar to extract. The factory must work harder, however, to extract any available sugar. "We use the same process for high purity beets as for low purity beets," Powers explains, "but poor quality beets slows the process down. Last year, with a poor quality beet, we produced about 11,500 hundredweight of sugar per day. This year, with a better purity beet, we produced about 15,500 hundredweight per day." He adds, "Last year we hauled away up to 15 loads of mud per day from the rock catchers. This year, with the cleaner beets, we're hauling about three loads of mud a day from the rock catchers." The factory received high purity beets this year from the growers. However, the mild winter storage conditions deteriorated the beets, with a resulting loss of sugar content in those beets left in storage piles over the winter. "The warm winter weather hurt us," Powers acknowledges. The production crews do not work in a vacuum. All departments support one another, and the production department relies heavily on the agriculture department, the maintenance crews, and the technical services division in order to complete the extraction process. The ag department supplies the best possible beets, scheduling the beet rehaul from the various receiving stations in as favorable a manner as possible. Technical services provides testing and quality assurance analyses. "A lot of the answers the technical services people get from their tests dictates what we do," Powers points out. "Our control depends on what technical services comes up with." Maintenance crews keep equipment operating smoothly

and at peak efficiency. "We all work together," Powers says. "All the

factory departments work together as a team for the best factory results,

and that includes safety and sanitation as well as fac The production crew finished up this year's slice on March 7. They then worked an additional three weeks to process the remaining thick juice stored in the thick juice tanks. During the summer months, Powers works with the maintenance department to discuss and set priorities of what needs to be done throughout the factory. He also works on his budget, determines chemical usage, decides what he will need for the next campaign, and works on safety and sanitation procedures. |

tory production.'

tory production.'